key switch guide

A key switch is a device enabling secure control of electrical systems through a physical key, ensuring authorized access and enhanced security across various critical applications and industries effectively.

1.1 What is a Key Switch?

A key switch is a device that requires a physical key to activate or deactivate an electrical circuit. It combines a mechanical key mechanism with an electrical switching system, ensuring secure control over various systems. Unlike standard switches, key switches prevent unauthorized access by requiring a specific key to operate. They are commonly used in security systems, industrial equipment, and vehicle ignition systems to provide an additional layer of control and protection. This mechanism ensures that only authorized individuals can activate or deactivate the associated circuit, making them essential for sensitive applications.

1.2 Importance of Key Switches in Security and Control Systems

Key switches play a vital role in enhancing security and control across various systems. By requiring a physical key for activation, they prevent unauthorized access, ensuring only authorized individuals can operate critical systems. This makes them indispensable in security systems, industrial equipment, and vehicle ignition systems. Their ability to restrict control ensures operational integrity and safety, particularly in sensitive environments. As a result, key switches are widely adopted in applications where secure and reliable operation is paramount, providing an additional layer of protection against unauthorized use or tampering.

How Key Switches Work

Key switches operate by requiring a physical key to align internal contacts, completing an electrical circuit and enabling control over connected systems or devices securely and effectively.

2.1 Mechanical Operation of Key Switches

A key switch functions mechanically by requiring a physical key to activate its internal mechanism. When the correct key is inserted and turned, it rotates a spindle or lever, moving internal contacts to either connect or disconnect an electrical circuit. This mechanical process ensures secure control, as the switch cannot be operated without the proper key. The design often includes anti-pick pins or other security features to prevent unauthorized use, making it a reliable method for controlling access in various systems and devices effectively.

2.2 Electrical Circuit Activation

Key switches activate electrical circuits by aligning internal contacts when the correct key is inserted and turned. This alignment completes the circuit, allowing electrical current to flow and power connected devices or systems. The activation process ensures controlled power distribution, enabling secure and reliable operation of the connected equipment. By requiring a physical key, these switches prevent unauthorized access and accidental activation, making them essential for maintaining safety and security in various applications. The precise mechanical-to-electrical interface ensures durability and consistent performance over time.

Types of Key Switches

Key switches vary by design, including rotary, toggle, and electronic types, each offering distinct functionalities for security, control, and specialized applications like industrial equipment and keyboards effectively.

3.1 Rotary Key Switches

Rotary key switches operate by turning a key to switch between multiple positions, often used in control panels, access doors, and public transportation systems. They offer durability and resistance to tampering, making them ideal for secure applications. These switches provide clear feedback with a rotational mechanism, ensuring precise control. Commonly found in industrial settings, rotary key switches are valued for their reliability and ability to handle complex switching requirements effectively.

3.2 Toggle Key Switches

Toggle key switches are designed with a lever-style mechanism that is activated by a physical key. Unlike rotary switches, they do not require rotation but instead move in a linear or rocker motion. These switches are commonly used in control panels, industrial equipment, and security systems. Toggle key switches are known for their simplicity and reliability, offering clear on/off or multi-position functionality. They are often preferred in applications where quick, precise control is necessary, making them a versatile option for various industrial and security-based environments.

3.3 Electronic Key Switches

Electronic key switches operate using electronic or digital signals rather than a physical mechanical key. They provide advanced security features, such as encryption and programmable access control, making them ideal for high-security applications. These switches are often integrated with digital systems, allowing for remote monitoring and control. Unlike traditional mechanical switches, electronic key switches minimize wear and tear and offer greater reliability. They are commonly used in modern security systems, industrial control panels, and smart devices, where digital authentication and secure access are critical. Their programmable nature ensures flexibility and adaptability to various security requirements.

Applications of Key Switches

Key switches are essential in security systems, industrial equipment, vehicle ignition, and mechanical keyboards, ensuring secure and controlled access across diverse applications and industries effectively.

4.1 Security Systems

In security systems, key switches ensure restricted access to critical functions, such as door locks, safes, and control panels. They provide an additional layer of protection against unauthorized use, ensuring that only designated personnel can activate or deactivate sensitive systems. These switches are commonly integrated into security infrastructure to enhance safety and prevent potential breaches. Their use is particularly prevalent in high-security environments, where controlling access is paramount. By requiring a physical key, they add a robust barrier against unauthorized access, making them indispensable in modern security setups.

4.2 Industrial Equipment Control

Key switches play a vital role in industrial equipment control, offering a secure and reliable method to operate machinery and systems. They ensure that only authorized personnel can activate or adjust equipment, preventing unauthorized access and potential accidents. These switches are often integrated into control panels, enabling precise operation of industrial processes. By requiring a physical key, they provide an additional layer of safety and operational integrity. This makes them essential in industries where machinery control must be strictly regulated, ensuring efficient and secure workflow management while maintaining production consistency and safety standards. Their durability and reliability further enhance their suitability for industrial environments.

4.3 Vehicle Ignition Systems

Key switches are integral to vehicle ignition systems, ensuring secure and controlled operation. They typically feature multiple positions, such as off, accessory, on, and start, allowing precise control over the vehicle’s functions. By requiring a physical key, these switches prevent unauthorized use and enhance security. Their design ensures that only authorized individuals can start or operate the vehicle, making them a critical component in modern transportation. The ignition key switch is a fundamental element in maintaining vehicle safety and operational integrity, balancing convenience with robust security measures to protect against theft and misuse effectively.

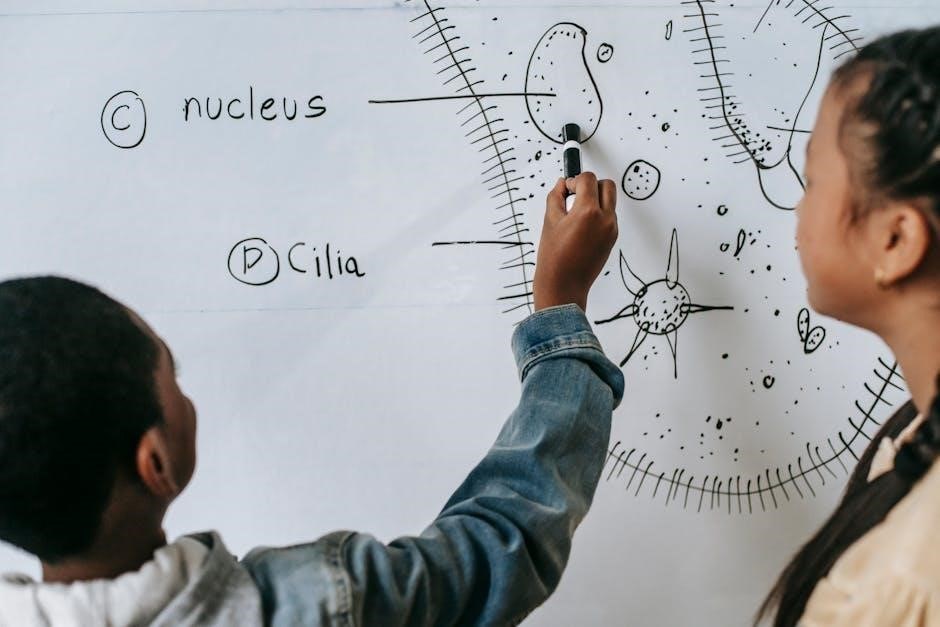

4.4 Mechanical Keyboards

Key switches are essential components in mechanical keyboards, providing the mechanism under each key that registers presses. These switches offer superior durability and tactile feedback compared to membrane keyboards, making them popular among typists and gamers. Mechanical keyboards allow users to choose from various switch types, such as linear, tactile, or clicky, each offering distinct actuation forces and sound levels. The choice of switch significantly impacts typing accuracy, comfort, and overall satisfaction. Understanding the differences in key switches helps users select the best option for their needs, enhancing productivity and personalized typing experiences.

Key Switch Types for Mechanical Keyboards

Mechanical keyboards utilize key switches offering distinct actuation forces, feels, and sounds. Common types include linear, tactile, and clicky switches, each catering to specific preferences and typing styles effectively.

5.1 Linear Switches

Linear switches are a popular choice for mechanical keyboards, offering a smooth, consistent actuation without a tactile bump. They feature a straight, uninterrupted motion from the top to the bottom of the key press. This design provides a seamless typing or gaming experience, as the user doesn’t feel a distinct feedback point. Linear switches are ideal for those who prefer a light, fluid keystroke and faster actuation. Common examples include Cherry MX Red and Kailh Red switches, which are favored by gamers and typists seeking a responsive, low-resistance input method. Their simplicity makes them durable and reliable for heavy use.

5.2 Tactile Switches

Tactile switches provide a distinct bump or feedback during key actuation, signaling to the user that the key has been pressed. This bump occurs midway through the key’s travel, allowing for precise control and reducing accidental key presses. Tactile switches, such as Cherry MX Brown or Kailh Brown, are popular among coders and typists who value the physical feedback without the audible click of clicky switches. They strike a balance between smooth actuation and noticeable resistance, making them versatile for both productivity and gaming. The tactile bump helps users know when a key is registered, promoting efficient typing and reducing typos.

5.3 Clicky Switches

Clicky switches combine tactile feedback with a distinct audible click, providing both a physical and auditory confirmation of key actuation. This makes them ideal for typists and gamers who rely on clear feedback to ensure accurate keystrokes. Clicky switches, such as Cherry MX Blue or Kailh Blue, feature a mechanism that produces a sharp, crisp sound when pressed. The sound is generated by a mechanism within the switch that creates a clicking noise as the key is actuated. These switches are often preferred by those who value both the tactile bump and the audible feedback, enhancing typing accuracy and user experience.

Choosing the Right Key Switch

Selecting the ideal key switch involves considering actuation force, travel distance, and sound preferences, ensuring optimal performance tailored to individual needs and applications effectively.

6.1 Actuation Force and Feel

Actuation force refers to the pressure needed to activate a key switch, ranging from light to heavy. Lighter switches (35g or less) suit fast typing, while heavier options (60g+) offer precise control. The “feel” depends on switch type—linear switches provide smooth actuation without tactile feedback, whereas tactile switches offer a noticeable bump, and clicky switches add audible feedback. Understanding personal preference for force and feel is crucial for selecting switches that enhance typing comfort and efficiency in mechanical keyboards or control systems. Proper selection ensures optimal performance and user satisfaction. Always consider these factors carefully.

6.2 Actuation Distance and Travel

Actuation distance is the distance a key must be pressed before it registers as an input, while total travel is the full range of key movement. Typically, actuation distance ranges from 1.5mm to 4mm, with total travel between 3mm and 5mm. Shorter actuation distances enable faster input registration, ideal for gaming and fast typing. Longer travel provides tactile feedback, reducing accidental presses. Understanding these measurements helps users choose switches that align with their preference for speed, feedback, or a balance of both, ensuring optimal performance for their specific needs and applications. Precise control is key to satisfaction.

6.3 Sound and Audible Feedback

Sound and audible feedback are critical factors in key switch selection, especially for mechanical keyboards. Clicky switches produce distinct audible clicks, providing clear confirmation of key presses, while tactile switches offer a subtle bump without noise. Linear switches are quiet, with no tactile or auditory cues. Silent switches are designed to minimize noise, ideal for shared workspaces. The choice depends on personal preference, environment, and typing style. Audible feedback can enhance typing accuracy and speed, but may be intrusive in quiet settings. Manufacturers often tailor switch designs to balance sound levels with performance, catering to diverse user needs and preferences effectively.

Installation and Wiring of Key Switches

Proper installation and wiring of key switches ensure reliable operation. Mount switches securely, connect terminals correctly, and follow circuit diagrams to avoid electrical issues and ensure safety always.

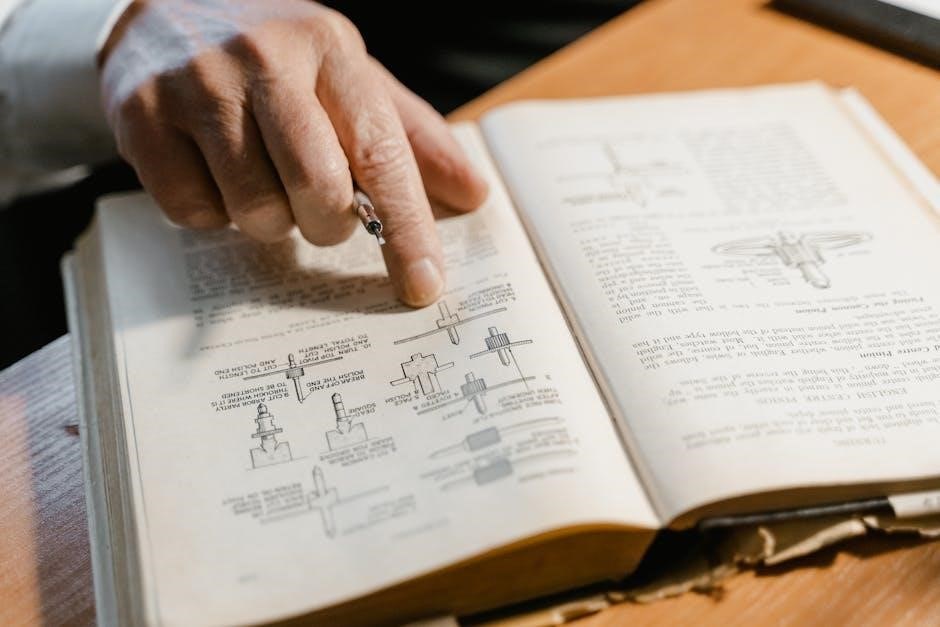

7.1 Basic Wiring Principles

Understanding basic wiring principles is crucial for installing key switches. Start by identifying the positive and negative terminals on the switch and the device it controls. Use appropriate gauge wire to ensure reliable connections and minimize resistance. Always disconnect power before wiring to avoid electrical shock. Connect the positive terminal to the power source and the negative terminal to the load, ensuring secure connections with solder or crimping. Double-check wiring diagrams specific to your key switch model to maintain proper circuit functionality and safety standards. Proper wiring ensures smooth operation and prevents damage to the system.

7.2 Mounting and Connectors

Proper mounting and connector selection are essential for key switch installation. Key switches are typically mounted using screws, clips, or adhesive, depending on the design. Ensure the switch is securely fastened to prevent movement or vibration. Connectors vary, with common types including solder terminals, screw terminals, or plug-and-play connectors. Choose connectors that match your wiring setup for reliable connections. For panel-mounted switches, ensure proper alignment and secure fastening to avoid mechanical failure. Consider using locking connectors for high-vibration applications to maintain stability. Always refer to the manufacturer’s specifications for mounting and connector compatibility to ensure optimal performance and longevity. Proper installation ensures durability and functionality.

Maintenance and Care

Regular cleaning with compressed air and lubrication of moving parts ensures optimal performance. Secure all connections and inspect periodically for wear and tear.

8.1 Cleaning Key Switches

Regular cleaning is essential to maintain the functionality and longevity of key switches. Use compressed air to remove dust and debris from the switch mechanism. For mechanical keyboards, gently pull off the keycaps and wipe the switches with a soft brush or a damp cloth. Avoid harsh chemicals or excessive moisture, as they can damage electrical components. Proper cleaning ensures smooth operation, prevents jamming, and maintains tactile feedback. Regular maintenance also helps reduce wear and tear, ensuring optimal performance over time. Always refer to the manufacturer’s guidelines for specific cleaning recommendations tailored to your key switch type.

8.2 Lubrication and Performance Optimization

Lubrication enhances the smoothness and durability of key switches by reducing friction and noise. Apply a small amount of silicone-based lubricant or dielectric grease to the switch’s moving parts. Avoid over-lubricating, as it can attract dust and degrade performance. For mechanical keyboards, focus on the stem and spring. Lubrication is particularly beneficial for switches with high usage or those in noisy environments. Regularly lubricating key switches ensures consistent actuation, reduces wear, and maintains optimal tactile feedback. This simple maintenance step can significantly extend the lifespan and improve the overall functionality of your key switches.

Common Issues and Troubleshooting

Common issues include sticky keys, intermittent contact, and worn-out components. Troubleshooting involves cleaning, inspecting wiring, and replacing faulty switches to restore functionality and reliability effectively.

9.1 Sticky or Jammed Keys

Sticky or jammed keys occur due to dirt, dust, or moisture accumulation inside the switch. This can hinder smooth operation, causing keys to get stuck or malfunction. Regular cleaning with compressed air or a soft brush is essential to remove debris. For severe cases, disassembling the switch and lubricating moving parts may be necessary. Ensuring the switch is dry and free from contaminants prevents jamming, maintaining optimal performance and longevity of the key switch. Proper maintenance is crucial to avoid such issues and ensure reliable functionality over time.

9.2 Intermittent Electrical Contact

Intermittent electrical contact occurs when the internal connections of a key switch fail to maintain consistent contact. This can result from worn-out contacts, dirt buildup, or corrosion. Symptoms include flickering lights, inconsistent operation, or complete loss of function. To resolve this, clean the contacts with a soft brush or electrical cleaner. In severe cases, replacing the switch may be necessary. Regular maintenance, such as cleaning and inspecting the contacts, can prevent intermittent issues. Ensuring a clean and dry environment for the switch also helps maintain reliable electrical contact and overall performance.